Opticon has range of DWC Pipe fittings which can be connected with coupler and elastomeric seal or butt welding. The elastomeric seal is placed inside the corrugation, thus avoiding the risk of being displaced during the coupling operation. The elastomeric seal of a particular profile not only avoids leakage, but also stops the groundwater entrance into the Pipe. The coupler must be installed on the Pipes with a constant and equally distributed thrust until the internal seat. The insertion of the seal between two corrugations is made by hand; in case of big diameters, this operation can be made by using a simple lever system.

To ease Pipe insertion, first lubricate the internal part of the coupling. With the lubrication of the seal, sand and soil may enter inside of the coupling causing tightness problems.

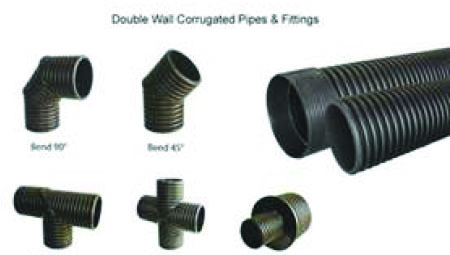

Special fittings are fabricated with OPTICON Pipes. Our workshop can fabricate special fittings following the purchaser drawing. It is possible to carry out connection between:

Thanks to its flexibility, the Pipe can be installed in any ground and slope. The flexibility helps to avoid all kind of obstacles with no need for bends. Elasticity helps to absorb all stresses caused by the ground settlements. It can be installed in any ground, in underground shafts, as well as in moist, wet & aggressive environments. Connection between two Pipe lengths is made through an easy-to-use jointing coupler for which no adhesive is required. For a quick connection between Pipe and coupler, we suggest using a lubricant and/or slipping product onto the coupler’s inside surface with insertion of elastomeric seals.

Opticon Pipes can be joined by different means, some of the jointing techniques are given below

The most widely used method for jointing individual lengths of a large diameter polyethylene pipe (>75mm) is by heat fusion of the pipe ends. This technique produces a permanent, economical and flow efficient joint. Field-site butt-welding may be made readily by trained operators using specially developed butt fusion machines.

Ⓒ Opticon Pipes